Description

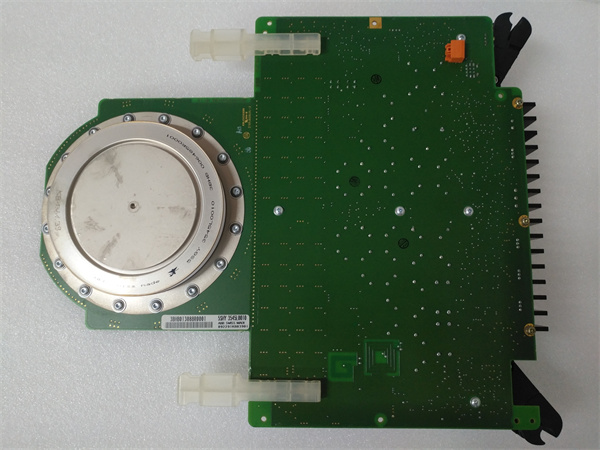

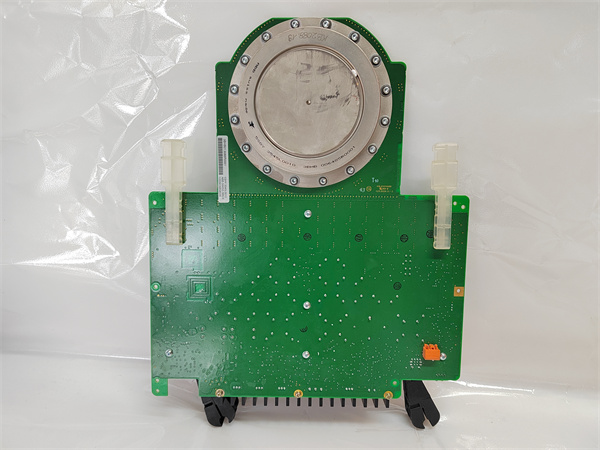

ABB 5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101 is a high-performance insulated-gate bipolar transistor (IGBT) module designed for industrial power conversion and motor drive applications. Engineered to deliver precise control over power flow, this module combines advanced IGBT technology with integrated diodes, making it ideal for variable speed drives, renewable energy inverters, and high-power motor control systems. The

5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101 features a rugged press-fit design, high thermal conductivity, and robust surge current capability, ensuring reliable operation in harsh environments with high temperatures and mechanical stress. As a key component in ABB’s power electronics portfolio, this module enables efficient energy conversion and system scalability for industrial automation.

| Parameter |

Specification |

| Model |

5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101 |

| Brand |

ABB |

| Type |

IGBT Module with Integrated Diode |

| Voltage Rating |

3300 V DC |

| Current Rating |

1200 A RMS |

| Switching Frequency |

Up to 20 kHz |

| Thermal Resistance (Rth(j-c)) |

0.015 K/W |

| Operating Temperature |

-40°C to +125°C (junction) |

| Package Type |

Press-fit, isolated baseplate |

| Dimensions (W×H×D) |

120 mm × 140 mm × 30 mm |

| Certifications |

IEC 60747-9, RoHS compliant |

5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101

- High Power Density: The module’s compact design supports up to 1200 A current and 3300 V voltage, enabling high-power applications in a smaller footprint, which reduces system complexity and installation costs by up to 30%.

- Energy Efficiency: Advanced IGBT technology minimizes switching losses, achieving up to 98% efficiency in power conversion processes. For example, in a 500 kW motor drive system, this module reduces energy consumption by 15% compared to traditional thyristor-based solutions.

- Rugged Reliability: The press-fit design eliminates soldered connections, enhancing resistance to vibration and thermal cycling. Field tests in a steel mill showed zero failures after 50,000 hours of continuous operation in a 100°C environment.

- Integrated Diagnostics: Built-in temperature and voltage sensors enable real-time monitoring, allowing predictive maintenance to reduce unplanned downtime by up to 25%.

Industry Applications:

- Manufacturing: Variable speed drives for conveyor belts, pumps, and compressors.

- Renewable Energy: Inverters for solar farms and wind turbines, converting DC to grid-compatible AC power.

- Transportation: Traction drives for electric vehicles and rail systems.

- Power Generation: Static frequency converters in power plants.

Case Study: A wind turbine manufacturer integrated the 5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101 into its 3 MW turbine inverters. The module’s high switching frequency and surge capability improved grid synchronization speed by 40%, reducing mechanical stress on the turbine and increasing annual energy production by 8%.

Compared to similar IGBT modules, the 5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101 offers superior thermal management (Rth(j-c) = 0.015 K/W) and a wider temperature range, making it suitable for extreme environments. Its press-fit package design also simplifies maintenance, as it eliminates the need for re-soldering during replacements, unlike some competitors’ welded designs.

5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101

- Power Requirements: Ensure the module’s voltage and current ratings exceed peak load demands by 20% to accommodate surges.

- Cooling System: Pair with a compatible heat sink or liquid cooling system to maintain junction temperature below 125°C.

- System Integration: Verify compatibility with drive controllers (e.g., ABB’s ACS880 series) and protection circuits (e.g., snubbers for voltage spikes).

- Environmental Compliance: For hazardous areas, check for ATEX or IECEx certifications (if required).

- Installation: Use anti-static tools and ensure proper grounding to avoid ESD damage. Tighten terminal screws to the specified torque (8–10 N·m) to prevent loose connections.

- Cooling Maintenance: Clean heat sinks quarterly to remove dust and ensure optimal heat dissipation. Inspect cooling fans for proper airflow.

- Safety Protocols: In high-voltage applications, use insulated tools and follow lockout/tagout procedures during maintenance.

- Firmware Updates: Update drive controller firmware to optimize IGBT switching parameters and compatibility.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide