Description

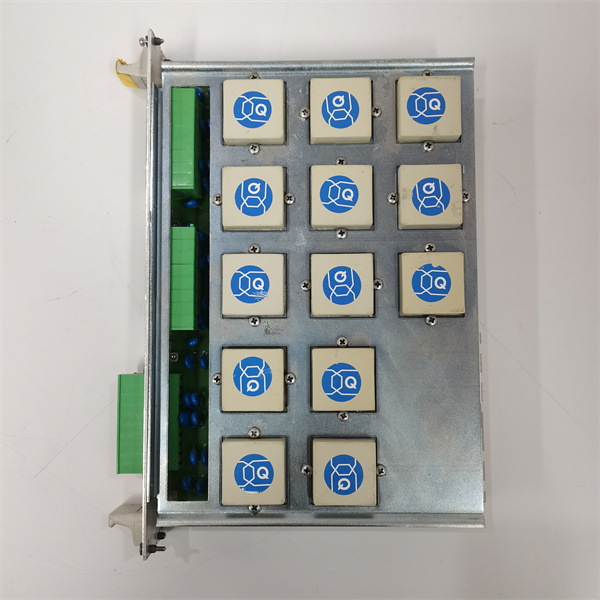

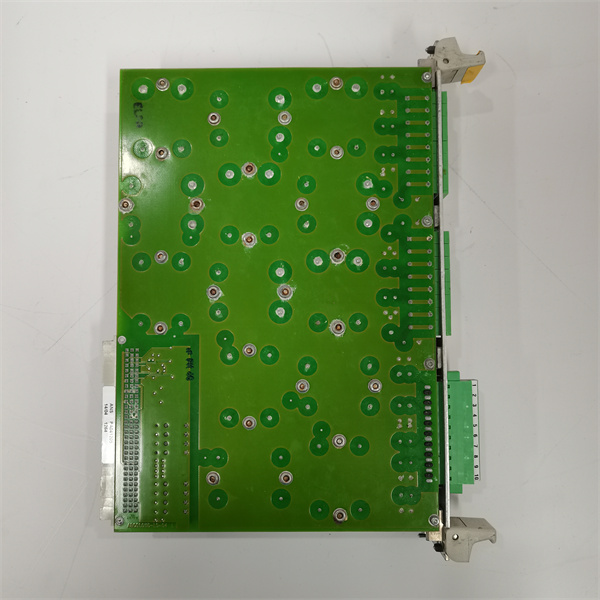

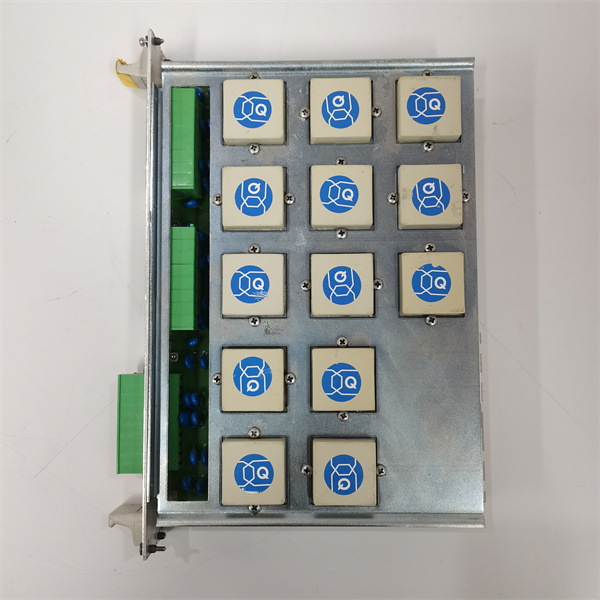

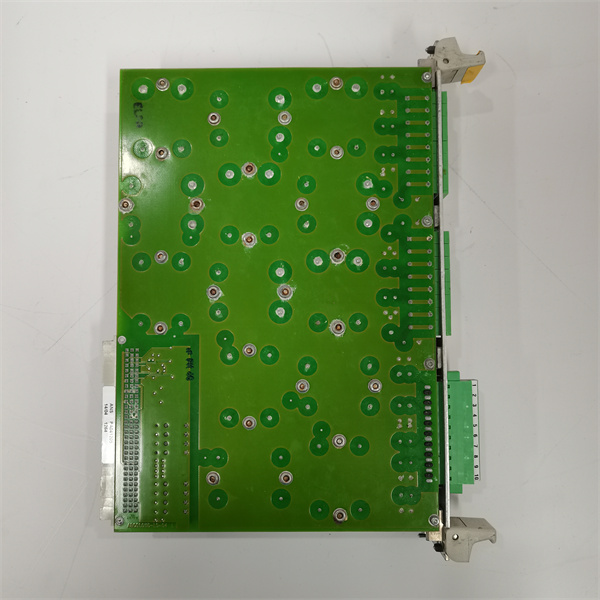

ABB 500MTM02 1MRK001967-AA 1HDF 930512 X010 is a high-performance PLC module designed to deliver precision control and reliability in industrial automation systems. As a key offering from ABB, a global leader in power and automation technologies, this module is engineered to meet the demanding requirements of complex industrial environments. The

500MTM02 series is renowned for its advanced functionality, making it a critical component in applications that require seamless data processing and real-time control.

The core function of the ABB 500MTM02 1MRK001967-AA 1HDF 930512 X010 is to serve as a motor control module, specifically designed to manage and monitor motor operations in industrial setups. It enables precise control of motor speed, torque, and direction while providing comprehensive diagnostic capabilities to ensure optimal performance. This module is ideal for industries that rely on high-efficiency motor management, such as manufacturing, energy, and process control, where reliability and energy efficiency are paramount.

| Parameter |

Details |

| Module Type |

Motor Control Module |

| Voltage Range |

Input: 24 V DC; Output: Variable (depending on motor specifications) |

| Control Features |

Speed control, torque control, start/stop regulation |

| Communication Interfaces |

Ethernet, PROFIBUS, Modbus RTU |

| Compatibility |

ABB AC 500 PLC system |

| Operating Temperature |

-20°C to +55°C |

| Dimensions |

150 mm (W) x 200 mm (H) x 100 mm (D) |

| Certifications |

CE, UL, CSA |

500MTM02 1MRK001967-AA 1HDF 930512 X010

The ABB 500MTM02 1MRK001967-AA 1HDF 930512 X010 offers several key advantages, including high precision control and energy efficiency. Its advanced algorithms enable smooth motor acceleration and deceleration, reducing mechanical stress and extending motor lifespan. The module’s built-in diagnostic tools provide real-time insights into motor health, such as overload detection and temperature monitoring, minimizing unexpected downtime and maintenance costs.

One of its standout features is flexible communication capabilities, allowing seamless integration with various industrial networks. This ensures easy integration into existing automation systems, enhancing overall system scalability. Additionally, the module’s compact design optimizes space in control panels, while its rugged construction ensures reliability in harsh environments with high vibration or humidity.

This module is widely used in industries such as manufacturing, water and wastewater treatment, mining, and power generation. It is particularly suited for applications involving pumps, fans, conveyors, and other motor-driven equipment where precise control and energy savings are critical.

Case Study: A leading automotive manufacturing plant implemented the ABB 500MTM02 module to manage conveyor motors in its assembly line. The module’s speed control capabilities reduced energy consumption by 20%, while its diagnostic features cut maintenance time by 30%. This resulted in improved production efficiency and significant cost savings.

Compared to similar motor control modules in the market, the ABB 500MTM02 stands out for its deep integration with ABB’s PLC ecosystem, ensuring plug-and-play compatibility and minimal configuration time. Its advanced energy management features and real-time diagnostics provide a competitive edge in applications requiring high operational efficiency. The module’s robust design and wide temperature range also make it suitable for more challenging environments than many comparable products.

500MTM02 1MRK001967-AA 1HDF 930512 X010

When selecting the ABB 500MTM02 1MRK001967-AA 1HDF 930512 X010, consider the following:

- Motor Specifications: Ensure the module’s voltage and current ratings match your motor’s requirements.

- Communication Needs: Verify compatibility with your plant’s existing network protocols (e.g., PROFIBUS, Modbus).

- Environmental Conditions: Assess factors like temperature, dust, and moisture to ensure the module’s durability in your setup.

- Scalability: Plan for future system expansions by ensuring the module can support additional motors or control points.

- Installation: Follow ABB’s guidelines for proper wiring and grounding to prevent electrical interference and ensure safe operation.

- Maintenance: Regularly update the module’s firmware to access the latest features and security patches.

- Safety: Always disconnect power before installing or servicing the module to avoid electrical hazards.

- Environmental Protection: In dusty or humid environments, use appropriate enclosures to protect the module from contaminants.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide