Description

The

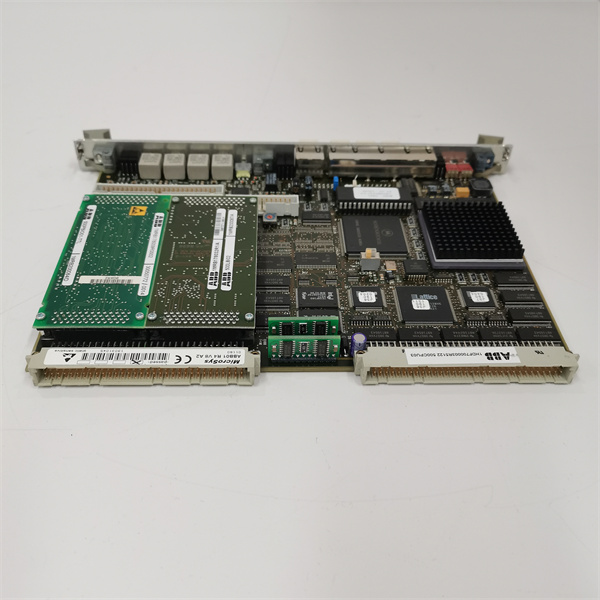

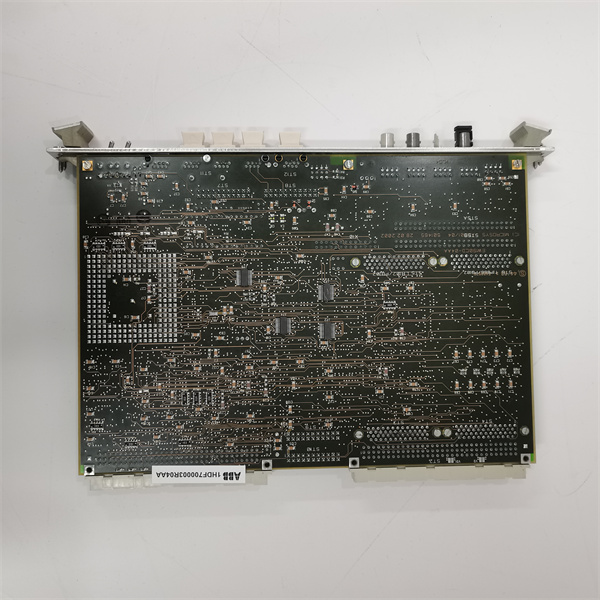

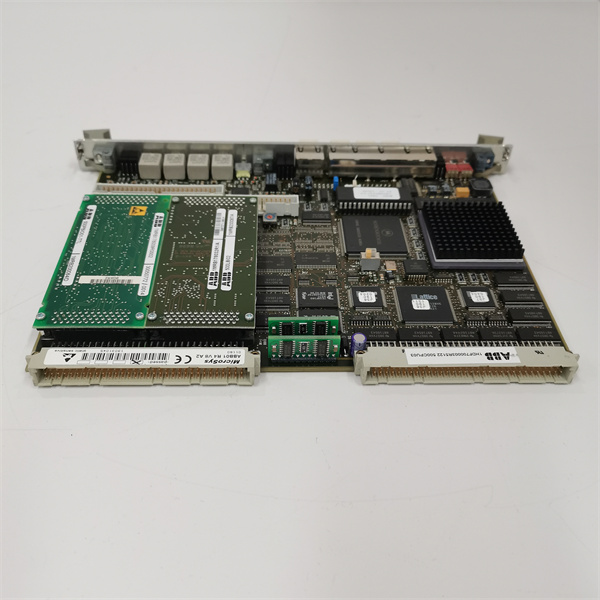

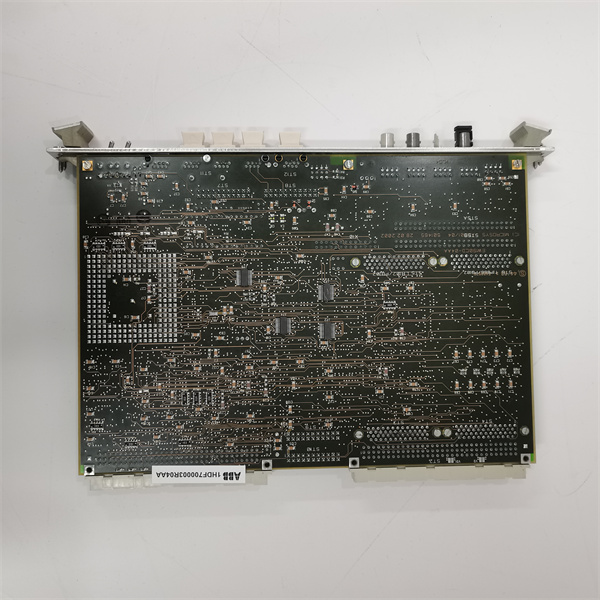

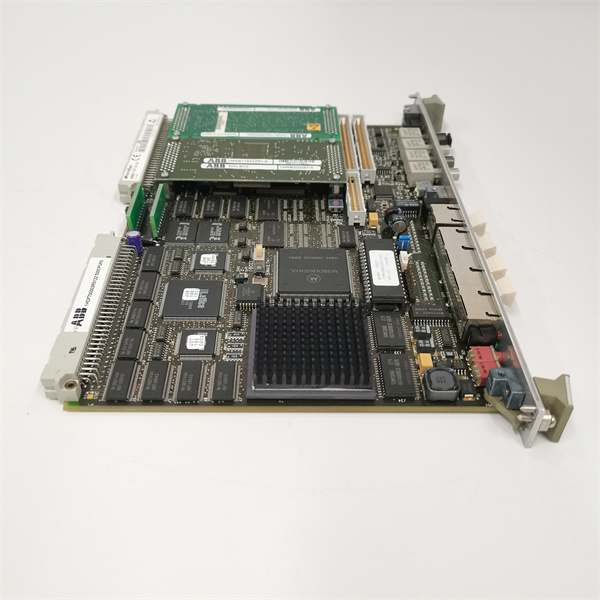

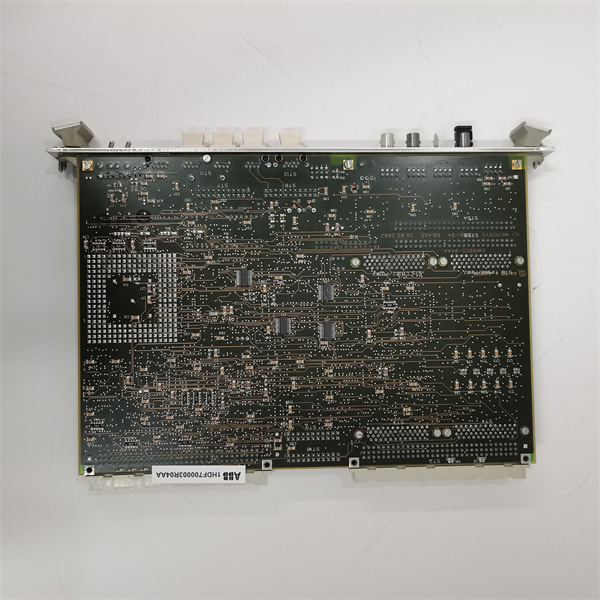

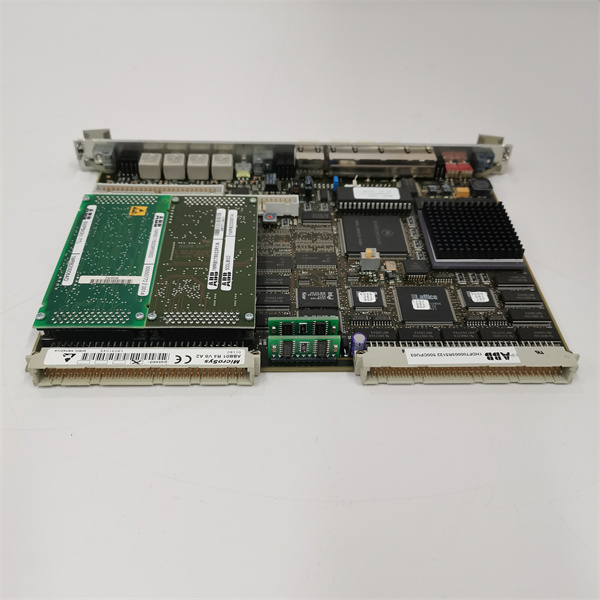

ABB 500CPU03 1HDF700003R5122 is a high-performance

central processing unit (CPU) designed for ABB’s

AC 500 series of programmable logic controllers (PLCs), catering to mid-to-large-scale industrial automation applications. As the computational core of the AC 500 system, the

500CPU03 1HDF700003R5122 delivers robust processing power, advanced communication capabilities, and modular flexibility, making it ideal for complex control tasks in industries such as manufacturing, energy, and infrastructure. This CPU serves as the backbone of automated systems, managing real-time data processing, logic execution, and coordination with I/O modules, drives, and supervisory systems.

Engineered with a 32-bit RISC processor and dual-core architecture, the ABB 500CPU03 1HDF700003R5122 supports high-speed control loops and multitasking, ensuring responsive operation even in demanding environments. Its core functions include support for IEC 61131-3 programming languages (Ladder Logic, Structured Text), real-time data logging, and integration with industrial networks via Ethernet/IP, Profibus DP, and Modbus TCP. Positioned as a scalable solution, the CPU enhances system efficiency by minimizing cycle times, enabling seamless integration with ABB’s 800xA Extended Automation System, and supporting advanced features like redundancy and cybersecurity protocols. The 500CPU03 1HDF700003R5122 embodies ABB’s commitment to delivering reliable, future-proof automation solutions for modern industrial challenges.

| Parameter Name |

Parameter Value |

| Product Model |

500CPU03 1HDF700003R5122 |

| Manufacturer |

ABB |

| Product Type |

PLC CPU Module |

| Processor |

32-bit RISC, dual-core, 500 MHz |

| Memory |

2 GB RAM, 8 GB Flash |

| Communication Interfaces |

Ethernet/IP, Profibus DP, Modbus TCP, RS-485 |

| I/O Capacity |

Up to 1,024 I/O points (via AC 500 I/O modules) |

| Redundancy Support |

Hot-swappable redundancy (optional) |

| Operating Temperature |

-20°C to +60°C |

| Dimensions (W×H×D) |

100 mm × 200 mm × 50 mm |

| Mounting Method |

DIN rail mounting |

| Certification |

CE, UL, IEC 61131-2, IEC 61508 (SIL2-ready) |

500CPU03 1HDF700003R5122

High-Speed Processing and Multitasking: The ABB 500CPU03 1HDF700003R5122 leverages its dual-core processor to execute complex control logic with sub-millisecond cycle times, ensuring precise coordination of multiple processes. Its advanced memory management allows for simultaneous execution of up to 32 tasks, making it suitable for applications requiring parallel processing, such as robotics, batch control, and conveyor systems.

Modular and Scalable Architecture: Designed for flexibility, the CPU supports seamless integration with ABB’s AC 500 I/O modules (e.g., digital, analog, communication), enabling customization for specific application needs. The hot-swappable design allows for system expansion or component replacement without downtime, a critical feature for 24/7 production environments.

Enhanced Connectivity and Cybersecurity: The CPU’s multi-protocol communication stack facilitates integration with diverse devices and systems, while built-in cybersecurity features (secure boot, encrypted communication, role-based access control) protect against unauthorized access and data breaches. This ensures compliance with modern industrial cybersecurity standards, making it suitable for critical infrastructure applications.

Real-Time Data and Diagnostics: The

500CPU03 1HDF700003R5122 includes real-time clock (RTC) and data logging capabilities, enabling detailed event tracking and trend analysis via ABB’s

Control Builder M software. Its diagnostic tools provide real-time insights into CPU load, memory usage, and I/O status, reducing troubleshooting time and enhancing proactive maintenance.

500CPU03 1HDF700003R5122

The ABB 500CPU03 1HDF700003R5122 is widely deployed in industries requiring reliable and flexible automation solutions. In manufacturing, it manages assembly lines, quality control systems, and packaging machinery, ensuring high throughput and product consistency. For energy and utilities, the CPU controls power generation units, substation automation, and microgrid systems, optimizing energy distribution and grid stability.

In food and beverage and pharmaceutical industries, the CPU’s compliance with hygienic standards and real-time control capabilities make it ideal for managing sterilization processes, conveyor systems, and batch record-keeping. It also excels in logistics and warehousing, where it coordinates automated guided vehicles (AGVs), sorting systems, and inventory management, enhancing operational efficiency. By addressing challenges like process complexity, data integration, and cybersecurity, the 500CPU03 1HDF700003R5122 empowers businesses to achieve higher productivity and agility.

- ABB 500CPU02 1HDF700002R5121: A predecessor model with single-core processing, suitable for simpler automation tasks.

- ABB 500CPU04 1HDF700004R5123: An upgraded variant with faster processing and enhanced redundancy features for mission-critical applications.

- ABB DI521 3BSE018123R1: A digital input module compatible with the AC 500 series, expanding the CPU’s I/O capabilities.

- ABB CI522 3BSE018125R1: A Profibus DP communication module for integrating the CPU with fieldbus devices.

- ABB TB521 Terminal Block: A terminal block accessory for secure wiring of digital signals to the CPU’s I/O modules.

Pre-installation preparation: Mount the 500CPU03 1HDF700003R5122 on a DIN rail in a grounded control cabinet, ensuring proper ventilation and separation from high-power components. Connect the CPU to the backplane power supply (24 V DC) and terminate Ethernet/fieldbus cables for communication with I/O modules and supervisory systems. Use Control Builder M to configure the CPU’s IP address, network protocols, and I/O module addressing, verifying compatibility with the automation network.

Maintenance recommendations: Regularly monitor the CPU’s diagnostic data via Control Builder M, checking for alerts on processor load, memory usage, or communication errors. Update firmware quarterly to incorporate new features and security patches, and maintain backups of project files on a secure network drive. Clean the CPU’s cooling slots with compressed air every six months to prevent dust accumulation, and inspect connections for signs of wear in high-vibration environments. In the event of a fault, replace the CPU with a pre-configured spare to minimize downtime, ensuring the new unit is calibrated and tested before full deployment.

ABB stands behind the 500CPU03 1HDF700003R5122 with a comprehensive quality assurance program, including rigorous testing for EMC compliance, thermal stability, and functional safety. The CPU is backed by a standard 3-year warranty, covering defects in materials and workmanship. ABB’s global technical support team provides 24/7 assistance for remote diagnostics, firmware updates, and on-site maintenance, ensuring minimal disruption to operations. Customers can access certified training programs and a dedicated online portal for documentation and software tools, reinforcing ABB’s commitment to delivering reliable, high-performance PLC solutions. With its advanced processing, scalability, and security features, the 500CPU03 1HDF700003R5122 is a strategic investment for future-proofing industrial automation systems.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide