Description

The

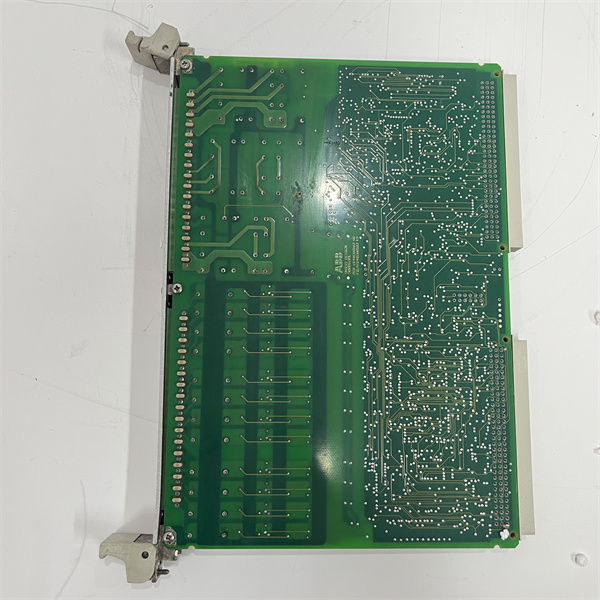

ABB 500BIO01 1MRB150005R1/J is a high-reliability

bi-directional I/O module designed for ABB’s

AC 500 programmable logic controller (PLC) system, serving as a critical interface for integrating discrete field signals in industrial automation. As part of the

AC 500 I/O family, this module enables bidirectional communication between the PLC and field devices, supporting both digital inputs (DI) and digital outputs (DO) in a single compact unit. The

500BIO01 1MRB150005R1/J features 16 configurable channels (8 DI + 8 DO or 16 DI/DO), making it ideal for applications requiring flexible I/O management, such as machine control, conveyor systems, or process automation in manufacturing, energy, and logistics.

Engineered with industrial-grade robustness, the module ensures signal integrity in harsh environments through electrical isolation (24 V DC) and noise immunity. Its core functions include real-time status monitoring, fault diagnostics, and hot-swappable maintenance, reducing downtime in critical operations. The 500BIO01 1MRB150005R1/J integrates seamlessly with ABB’s Control Builder AC 500 software, enabling quick configuration of channel types, diagnostic thresholds, and safety interlocks. Positioned as a scalable solution, the module enhances system efficiency by minimizing wiring complexity and supporting modular expansion in AC 500 PLC racks.

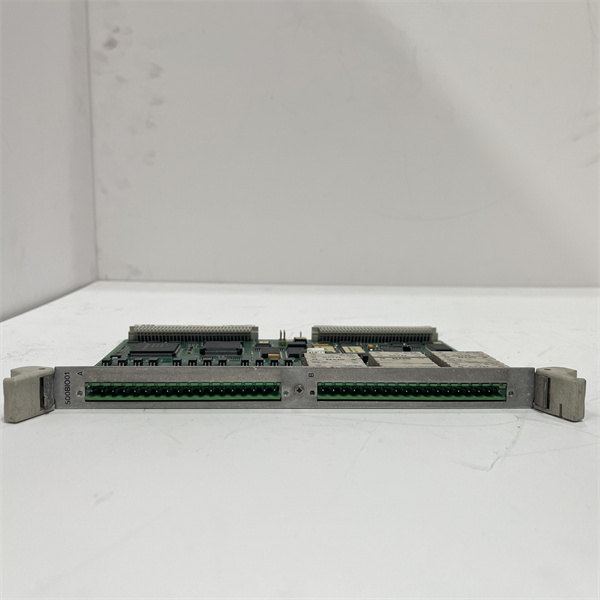

| Parameter Name |

Parameter Value |

| Product Model |

500BIO01 1MRB150005R1/J |

| Manufacturer |

ABB |

| Product Type |

Bi-Directional Digital I/O Module |

| Channels |

16 channels (configurable as 8 DI + 8 DO or 16 DI/DO) |

| Signal Type |

24 V DC (TTL/CMOS compatible) |

| Electrical Isolation |

500 V rms (channel-to-system ground) |

| Input Filter Time |

0.2–32 ms (configurable per channel) |

| Output Current |

2 A per channel (resistive load) |

| Response Time |

<1 ms (signal detection to output) |

| Operating Temperature |

-25°C to +60°C |

| Dimensions (W×H×D) |

36 mm × 100 mm × 110 mm |

| Mounting Method |

DIN rail (AC 500 I/O rack) |

| Certification |

CE, UL, IEC 61131-2, RoHS |

500BIO01 1MRB150005R1

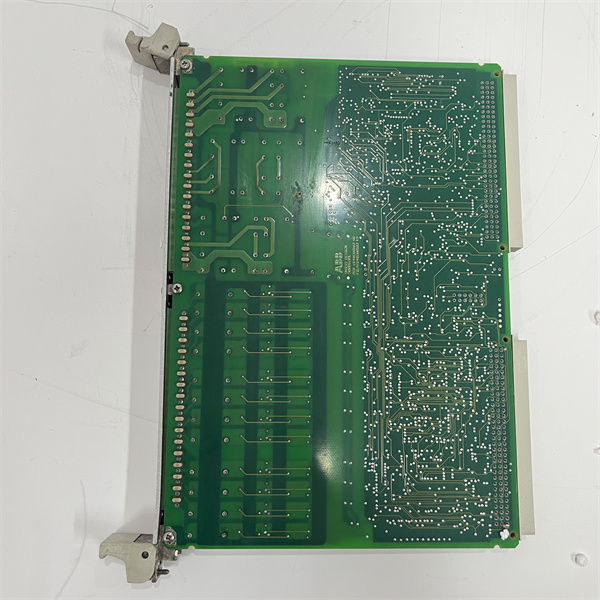

Flexible Channel Configuration: The 500BIO01 1MRB150005R1/J offers dual-mode operation, allowing each channel to be configured as a digital input or output via software. This versatility reduces inventory needs, as a single module can address both signal monitoring (e.g., limit switches) and control (e.g., solenoid valves) in diverse applications. For example, in a packaging line, channels can be assigned to detect product presence (DI) and activate label printers (DO) within the same module.

Rugged Design for Harsh Environments: With a wide temperature range and conformal-coated PCBs, the module withstands vibration, dust, and moisture, making it suitable for outdoor installations or factory floors. The 500 V rms isolation protects against voltage spikes from inductive loads (e.g., motors), while short-circuit/overload protection safeguards output channels from damage.

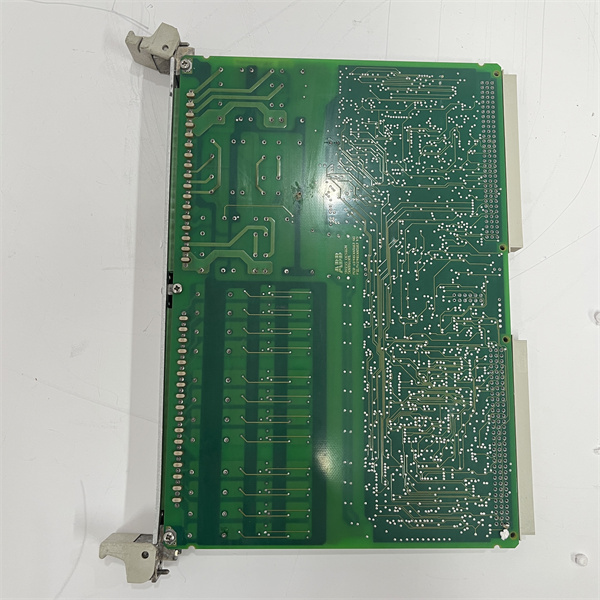

Seamless System Integration: Fully compatible with ABB’s AC 500 PLCs (e.g., PM590), the module connects via the CANopen fieldbus, enabling real-time data exchange with minimal latency. Engineers can use Control Builder AC 500 to assign channel addresses, enable diagnostic alarms, and implement safety functions (e.g., emergency stop latching) using pre-defined function blocks, reducing programming time by up to 30%.

Hot-Swappable Maintenance: The module supports live replacement without powering down the PLC system, minimizing downtime during repairs or upgrades. Built-in LED indicators provide instant feedback on channel status (e.g., green for normal operation, red for fault), enabling rapid fault isolation. For predictive maintenance, the module logs diagnostic data (e.g., output switch cycles) accessible via the PLC’s web interface.

500BIO01 1MRB150005R1

The ABB 500BIO01 1MRB150005R1/J is widely deployed in industries requiring flexible, reliable I/O control:

- Manufacturing: Manages discrete signals in automotive assembly lines, such as detecting part positions on conveyors (DI) and actuating pneumatic grippers (DO). In a semiconductor factory, it monitors cleanroom door status (DI) and controls UV sterilization lamps (DO).

- Logistics and Automation: Supports AGV (automated guided vehicle) systems by monitoring charging station availability (DI) and controlling conveyor motor starters (DO). In warehouses, it coordinates palletizers by detecting empty pallets (DI) and triggering robotic arm movements (DO).

- Energy and Utilities: Monitors circuit breaker positions (DI) and controls pump starters (DO) in water treatment plants. For renewable energy, it manages solar tracker actuators (DO) and detects panel cleaning system status (DI) in solar farms.

- Process Industries: Used in food processing to monitor conveyor belt jams (DI) and activate reject mechanisms (DO), ensuring compliance with hygiene standards. In chemical plants, it supports safety interlocks by detecting valve positions (DI) and triggering emergency shutdowns (DO).

- ABB 500DI09 1MRK001008R101: A 16-channel digital input module for high-density monitoring applications.

- ABB 500DO08 1MRK001010R101: A 16-channel digital output module for heavy-duty switching (3 A per channel).

- ABB PM590-ETH PLC Controller: The primary controller for the AC 500 system, offering Ethernet connectivity and advanced processing.

- ABB TB521 Terminal Block: A rugged terminal block for secure field wiring, compatible with the 500BIO01.

- ABB CI522 Profibus DP Module: Enhances the 500BIO01’s connectivity in hybrid fieldbus networks.

Pre-installation preparation: Mount the 500BIO01 1MRB150005R1/J in an AC 500 I/O rack, ensuring proper grounding and ventilation. Use shielded cables for field connections, terminating DI signals (e.g., switches) and DO loads (e.g., relays) to the module’s terminal block. Configure channel modes and filter times via Control Builder AC 500, and verify signal integrity using the module’s built-in test functions.

Maintenance recommendations: Regularly inspect LED indicators for fault signals and clean dust from ventilation slots quarterly. In high-vibration environments, retighten terminal connections annually. Test hot-swappable functionality biannually to ensure rapid module replacement capability. Update firmware via the PLC’s firmware manager to incorporate bug fixes or new features, and maintain backups of I/O configurations for quick restoration.

ABB stands behind the 500BIO01 1MRB150005R1/J with a 3-year warranty, covering defects in materials and workmanship. ABB’s global technical support team provides 24/7 assistance for troubleshooting, configuration guidance, and remote diagnostics, ensuring minimal disruption to operations. Customers can leverage ABB’s certified training programs to optimize module usage and access a dedicated online portal for firmware updates and technical documentation, reinforcing the 500BIO01’s role as a trusted automation component.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide