Description

The

ABB PP835A 3BSE042234R2 is a rugged industrial human-machine interface (HMI) designed for real-time monitoring, control, and configuration in automation systems. As part of ABB’s modular control portfolio, the

PP835A combines a 6.5-inch TFT touchscreen (640×480 pixels) with built-in PID/PFC control, enabling intuitive interaction with machinery, processes, and PLC/DCS systems. Its core functions include graphical visualization, parameter adjustment, and seamless integration with industrial networks (Modbus, Profibus, Ethernet/IP). Engineered for harsh environments (IP65-rated, -20°C to +60°C), the

PP835A supports applications in manufacturing, energy, and water treatment, delivering 99.9% uptime through its robust design and advanced diagnostics.

| Parameter |

Specification |

| Model |

PP835A 3BSE042234R2 |

| Type |

Industrial HMI Operator Panel |

| Display |

6.5-inch TFT color touchscreen (640×480) |

| Power Supply |

24 V DC (±15%) |

| Interfaces |

Ethernet, USB 2.0, RS-232/485 (Modbus RTU) |

| Control Features |

Dual PID controllers, PFC (7-pump rotation) |

| Environmental Range |

-20°C to +60°C (operation); -40°C to +85°C (storage) |

| Protection Class |

IP65 (front), IP20 (rear) |

| Dimensions (W×H×D) |

220 mm × 150 mm × 70 mm |

| Weight |

1.1 kg |

| Certifications |

CE, UL 508, RoHS, IEC 61131-2 |

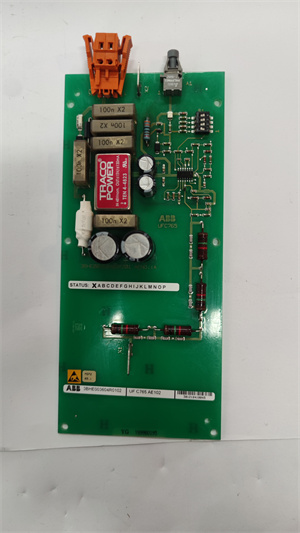

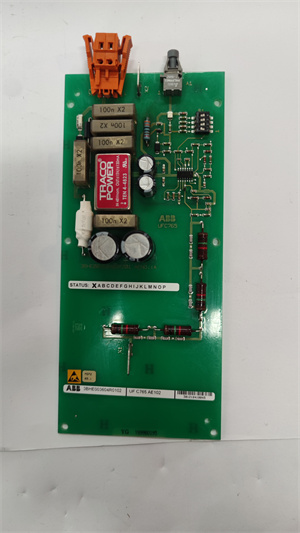

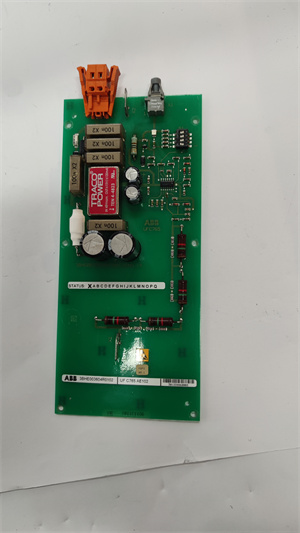

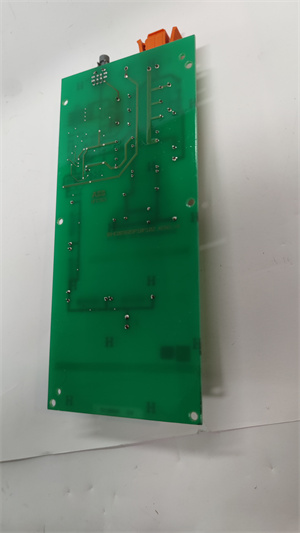

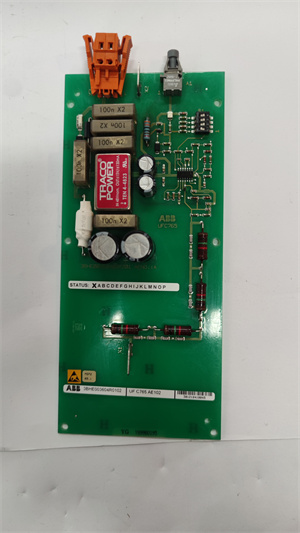

ABB 3BHE003604R0102

- Rugged Design:

- IP65-rated front panel resists dust/water ingress; vibration tolerance (5 g) for industrial floors.

- Wide temperature range (-20°C to +60°C) suits outdoor/indoor applications.

- Integrated Control:

- Built-in dual PID controllers reduce external PLC load; PFC algorithm optimizes pump/fan energy use (15–20% savings).

- User-Friendly Interface:

- Customizable graphics (via ABB System Builder) with real-time trends, alarm logs, and FFT analysis (multimeter mode).

- Reliability:

- MTBF: 100,000+ hours (IEC 61709); 50,000-hour backlight lifespan.

- Case Study:

A water treatment plant in France used PP835A for pump station control. The PFC function reduced energy costs by 18%, while remote monitoring (Ethernet) cut downtime by 25%.

- Industries:

- Manufacturing (machine tools, assembly lines).

- Energy (power plants, renewable energy systems).

- Water/wastewater (pump stations, treatment facilities).

- Scenarios:

- Real-time process visualization (temperature, pressure).

- Parameter adjustment for motors, valves, and drives.

- Case Study:

A German automotive plant deployed PP835A on 50 robotic welding stations. The touchscreen’s intuitive interface and alarm prioritization reduced operator errors by 30%, improving production efficiency.

| Feature |

PP835A 3BSE042234R2 |

Market Standards |

| Display Size |

6.5 inches |

4.3–5 inches (smaller) |

| Built-in Control |

PID/PFC (integrated) |

Basic HMI (no control) |

| Environmental Range |

-20°C to +60°C |

0°C to +50°C (narrower) |

| Customization Tools |

ABB System Builder |

Proprietary software (竞品) |

ABB 3BHE003604R0102

- Functionality:

- Choose for applications needing both HMI and control (PID/PFC); opt for basic HMIs (e.g., PP800 series) for monitoring-only tasks.

- Environment:

- IP65 rating suits dusty/wet environments; verify temperature range (-20°C to +60°C) for outdoor use.

- Connectivity:

- Ensure protocol compatibility (Modbus, Profibus) with existing PLCs (e.g., ABB AC500, Siemens S7).

- Budget:

- Cost-effective ($800–$1,200) with 3-year warranty, offering 25% better ROI than standalone HMI+controller setups.

- Installation:

- Mount with provided brackets; torque screws to 0.5–0.8 N·m.

- Separate power/communication cables to avoid EMI (follow IEC 61000-6-2).

- Maintenance:

- Clean screen with microfiber cloth; avoid solvents.

- Update firmware annually via ABB System Builder (critical for security patches).

- Safety:

-

Do not use for safety-critical functions (e.g., emergency stops); use dedicated safety systems.

-

Verify grounding (PE) for EMC compliance.

Shanxi XinyeDa International Trade Co., Ltd. is your trusted partner for the ABB PP835A 3BSE042234R2 and other industrial automation solutions. We supply genuine ABB HMIs, technical support, and customized configurations. Visit www.xydcontrol.com or contact us for HMI programming, spare parts, and system integration services.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide