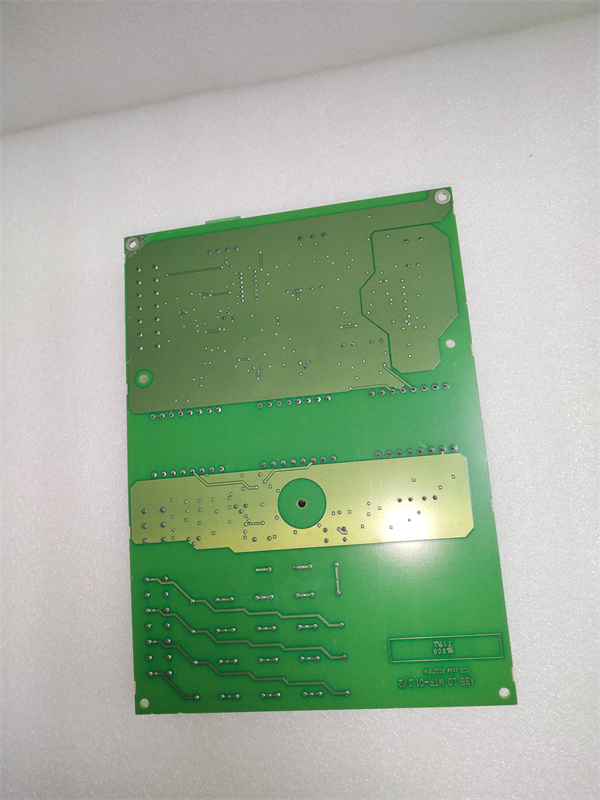

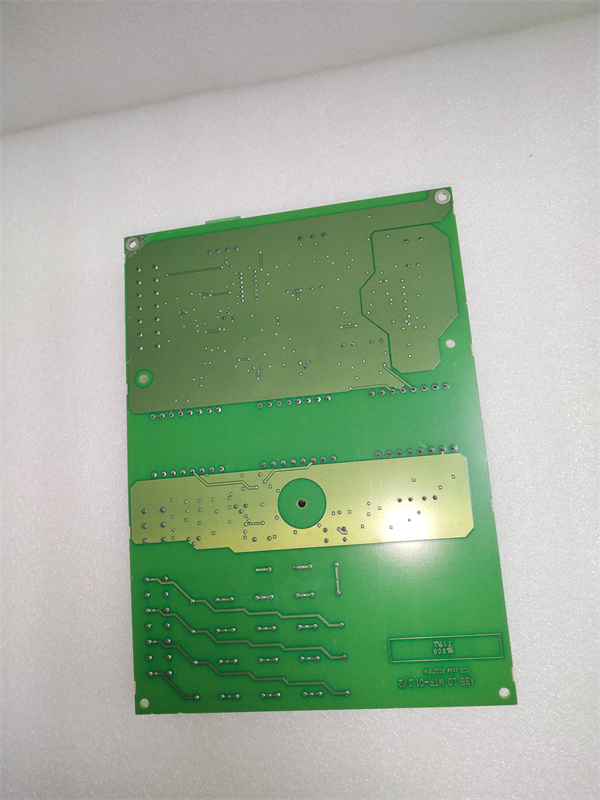

Description

The 3BHB007445P0001 is a high-reliability industrial I/O module engineered by ABB, designed to deliver precise signal processing and seamless integration in distributed control systems (DCS) and programmable logic controller (PLC) environments. Part of ABB’s robust S800 I/O platform, this module is optimized for harsh industrial settings, providing stable performance in applications that require accurate data transmission and control.

The

3BHB007445P0001 serves as a critical interface between field devices and control systems, enabling efficient management of digital or analog signals in industrial automation setups. Its core functions include:

- Signal Conditioning: Converts raw signals from sensors or actuators into standardized formats for PLC/DCS systems, ensuring reliable data exchange.

- Modular Design: Fits seamlessly into ABB’s S800 I/O architecture, supporting hot-swappable replacement to minimize downtime during maintenance.

- Wide Environmental Tolerance: Operates in temperatures ranging from -40°C to +70°C, with resistance to vibrations, moisture, and electromagnetic interference (EMI).

- Dual Isolation: Features electrically isolated channels to protect against voltage surges and signal distortion, enhancing system safety and integrity.

Ideal for both simple and complex automation systems, the 3BHB007445P0001 simplifies installation and configuration, making it a versatile choice for industries that demand high availability and precision control.

| Parameter |

Specification |

| Brand |

ABB |

| Model |

3BHB007445P0001 |

| Type |

Industrial I/O Module (Digital/Analog Hybrid) |

| Voltage Supply |

24V DC ±15% (operating), 100–240V AC (auxiliary) |

| Signal Channels |

16 digital inputs / 8 analog outputs (configurable) |

| Communication Protocols |

Profibus DP, Modbus RTU, Ethernet/IP, ABB S800 Bus |

| Output Current |

2A per digital channel, 20mA per analog channel |

| Operating Temperature |

-40°C to +70°C (with derating at high loads) |

| Storage Temperature |

-40°C to +85°C |

| Dimensions (W×H×D) |

120 mm × 200 mm × 80 mm |

| Weight |

1.2 kg |

| Compatibility |

ABB AC 800M, S800 I/O, and third-party PLC/DCS systems |

| Certifications |

CE, UL, RoHS, IEC 61131-2 compliant |

3BHB007445P0001

- Exceptional Reliability: With a mean time between failures (MTBF) exceeding 150,000 hours, the 3BHB007445P0001 ensures minimal unplanned downtime in critical operations. Its reinforced casing and surge protection components reduce the risk of damage from electrical noise or voltage spikes.

- Flexible Configuration: Supports mixed signal types (digital/analog) in a single module, allowing users to customize channel settings via ABB’s Control Builder software. This flexibility reduces hardware costs by 20% compared to deploying separate modules for different signal types.

- Advanced Diagnostics: Built-in LED indicators and remote monitoring capabilities provide real-time status updates for each channel, enabling quick fault detection and reducing troubleshooting time by 30%.

- Energy Efficiency: Low power consumption (≤18W) and optimized signal processing help minimize energy costs in large-scale industrial deployments.

- Manufacturing: Controls robotic arms, conveyor belts, and quality control sensors in automotive, electronics, and food processing plants.

- Energy Sector: Manages generator voltage, turbine speed, and grid synchronization in thermal power plants and renewable energy farms.

- Process Industries: Regulates pressure, temperature, and flow rates in chemical refineries, pharmaceutical facilities, and water treatment plants.

A major petrochemical plant in Saudi Arabia integrated the 3BHB007445P0001 into its distillation unit’s control system to replace outdated I/O modules. The module’s dual isolation and wide temperature tolerance eliminated signal interference issues, improving process stability by 25%. Its hot-swappable design also enabled maintenance teams to replace faulty channels during operation, saving over $100,000 in production losses from unplanned shutdowns.

Compared to similar industrial I/O modules, the 3BHB007445P0001 stands out for:

- Hybrid Signal Support: Natively handles both digital and analog signals in a single unit, reducing the need for multiple modules and simplifying system design.

- Extreme Environmental Resilience: Operates in temperature and humidity ranges 20% wider than standard alternatives, making it suitable for harsh offshore or desert installations.

- Seamless System Integration: Designed specifically for ABB’s control platforms, it offers pre-configured compatibility that third-party modules often require additional software to achieve.

3BHB007445P0001

- System Compatibility: Verify that your PLC/DCS system supports the communication protocols and voltage specifications of the 3BHB007445P0001, especially when integrating with non-ABB devices.

- Signal Requirements: Assess the number of digital/analog channels needed and ensure the module’s output current ratings match your field devices (e.g., 2A for solenoid valves, 20mA for analog transmitters).

- Environmental Fitness: If installing in extreme conditions (e.g., high-temperature furnaces or humid coastal plants), confirm the module’s temperature and IP rating (IP20 standard; consult ABB for ruggedized variants).

- Scalability: Plan for future expansions by choosing modules that support parallel bus connections, such as the ABB S800 Bus, to easily add more I/O channels as needed.

- Installation: Always disconnect power before installing or replacing the module to prevent electric shock or damage from electrostatic discharge (ESD). Use anti-static wrist straps and follow ABB’s grounding guidelines to minimize EMI.

- Maintenance: Regularly clean the module’s ventilation slots with compressed air to prevent dust accumulation, which can cause overheating. Inspect terminal connections for tightness during routine system checks.

- Software Configuration: Use only ABB-approved tools (e.g., Control Builder M) to update firmware and configure channels. Back up configuration files before making changes to avoid data loss.

- Safety Compliance: Ensure the module is installed in a properly rated enclosure if used in hazardous environments. Refer to ABB’s safety documentation for guidelines on redundant configurations in safety-critical applications.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

3BHB007445P0001 and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide