Description

The

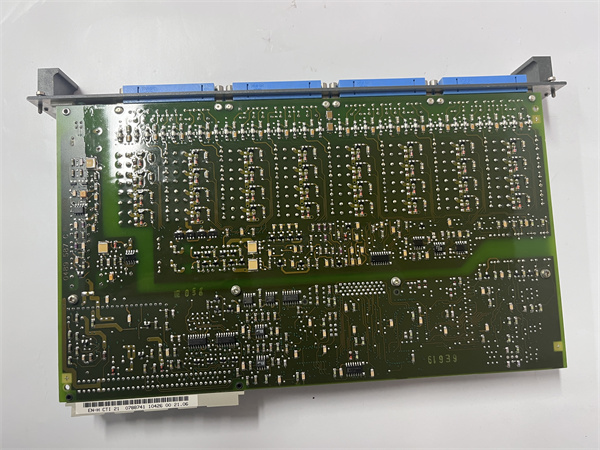

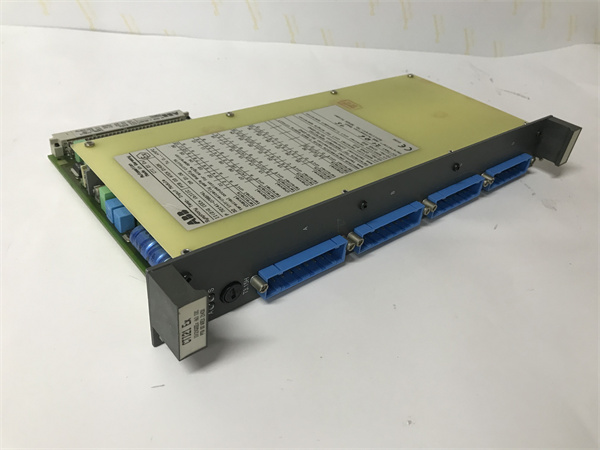

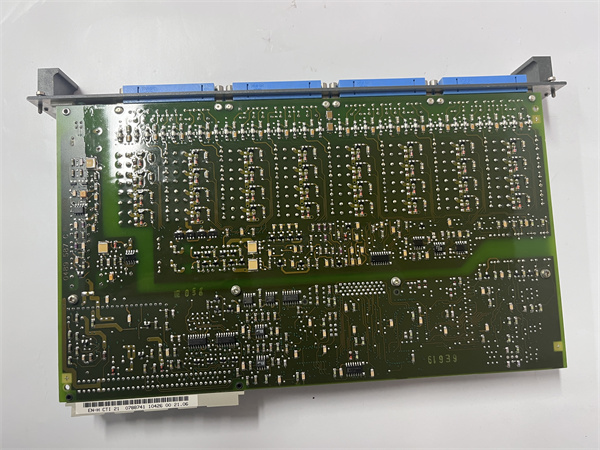

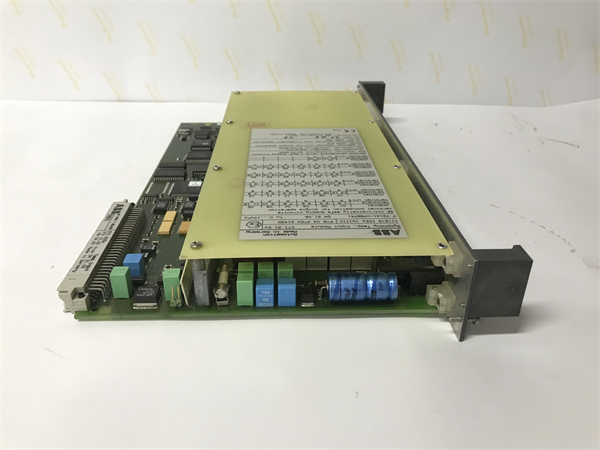

ABB 3BDH000741R1 CTI 21-P EX is a high-performance explosion-proof control module designed for critical industrial environments where safety and reliability are paramount. As part of ABB’s advanced CTI series, this module is engineered to deliver precise control and monitoring capabilities in hazardous areas, such as petrochemical plants, refineries, and gas processing facilities. The

3BDH000741R1 CTI 21-P EX combines robust hardware with intelligent software to manage complex automation tasks while adhering to strict explosion-proof standards, ensuring operational continuity in volatile conditions.

This module serves as a vital component in distributed control systems (DCS), enabling real-time data processing, signal conditioning, and safety interlocking. Its core functions include analog and digital input/output processing, fault detection, and communication with other control devices via standardized protocols. The ABB 3BDH000741R1 CTI 21-P EX is designed to withstand harsh environmental factors, such as extreme temperatures, moisture, and corrosive atmospheres, making it a trusted solution for industries requiring ruggedized automation equipment. By integrating seamlessly with ABB’s broader portfolio of control systems, this module enhances system scalability and reduces downtime, delivering long-term value for industrial operators.

| Parameter Name |

Parameter Value |

| Product Model |

3BDH000741R1 CTI 21-P EX |

| Manufacturer |

ABB |

| Product Type |

Explosion-Proof Control Module |

| Certification |

ATEX, IECEx (Explosion-proof standards for hazardous areas) |

| Input Voltage Range |

24 V DC ±10% |

| Operating Temperature |

-40°C to +70°C |

| Storage Temperature |

-40°C to +85°C |

| Humidity Resistance |

5% to 95% RH (non-condensing) |

| Communication Protocol |

Modbus RTU, PROFIBUS DP |

| I/O Channels |

16 analog inputs, 8 digital outputs |

| Signal Types |

4-20 mA, 0-10 V, dry contacts |

| Enclosure Material |

Stainless steel with epoxy coating |

| Dimensions |

150 mm (H) x 100 mm (W) x 80 mm (D) |

3BDH000741R1 CTI 21-P EX

Reliable Explosion-Proof Design: The 3BDH000741R1 CTI 21-P EX is certified for use in Zone 1/21 and Zone 2/22 hazardous areas, ensuring compliance with international safety regulations. Its robust enclosure and intrinsic safety barriers prevent sparks or heat from escaping, minimizing the risk of ignition in flammable environments.

Advanced Multifunctionality: This module supports a wide range of input/output signals, allowing it to interface with various sensors, actuators, and field devices. Its built-in microprocessor enables real-time data analysis and predictive maintenance, reducing the need for manual intervention and enhancing system efficiency.

Environmental Resilience: Engineered to thrive in harsh conditions, the module features corrosion-resistant materials and a ruggedized design that withstands vibration, shock, and aggressive chemicals. This durability ensures consistent performance in offshore platforms, chemical plants, and other challenging industrial settings.

Seamless System Integration: Compatible with ABB’s Control Builder software, the 3BDH000741R1 CTI 21-P EX simplifies configuration and commissioning. Its support for multiple communication protocols enables easy integration with existing DCS and PLC systems, facilitating scalable automation architectures.

The ABB 3BDH000741R1 CTI 21-P EX is ideally suited for industries where explosion-proof control is non-negotiable. In the oil and gas sector, it monitors pressure, temperature, and flow rates in extraction sites and processing units, ensuring safe operation while optimizing production yields. In chemical manufacturing, the module controls reactive processes and manages safety interlocks to prevent hazardous incidents. It also excels in pharmaceutical and food processing environments, where precise control of sterile or volatile environments is critical.

Additionally, this module is used in marine and offshore applications, such as rigs and tankers, where it withstands saltwater corrosion and extreme weather conditions while managing cargo handling systems and engine controls. By providing reliable automation in high-risk areas, the

3BDH000741R1 CTI 21-P EX helps industries meet regulatory requirements, reduce operational risks, and maintain uninterrupted production.

3BDH000741R1 CTI 21-P EX

- ABB 3BDH000742R1 CTI 22-P EX: A higher-channel version with 32 analog inputs, designed for large-scale systems requiring expanded I/O capacity.

- ABB 3BDH000740R1 CTI 20-P EX: A basic model with fewer I/O channels, suitable for smaller-scale applications or budget-sensitive projects.

- ABB 3BHB003430R0101 PM866AK01: A complementary processor module for enhanced control logic and data processing in ABB’s AC 800M system.

- ABB 3HAC025948-001 DSQC652: A digital I/O module for robotic control systems, integrating with the CTI series for hybrid automation solutions.

- ABB 3BSE018166R1 AI830: An analog input module optimized for high-precision temperature and pressure sensing in non-hazardous areas.

Pre-installation preparation: Ensure the installation site complies with explosion-proof standards, including proper grounding and cable gland sealing. Verify that the power supply matches the 3BDH000741R1 CTI 21-P EX’s voltage requirements (24 V DC) and that all wiring follows anti-electromagnetic interference (EMI) guidelines. Use certified tools to avoid sparking during installation, and secure the module in a vibration-dampened enclosure.

Maintenance recommendations: Regularly inspect the module for physical damage or corrosion, particularly in high-humidity or corrosive environments. Perform firmware updates using ABB’s dedicated software to ensure compatibility with the latest safety protocols and functional enhancements. Monitor diagnostic indicators for early detection of faults, such as failing sensors or communication errors. Schedule annual calibration of analog inputs to maintain measurement accuracy, and replace backup batteries as recommended to preserve configuration data.

ABB stands behind the 3BDH000741R1 CTI 21-P EX with a comprehensive quality assurance program, including rigorous testing to ensure compliance with international standards. The module is backed by a standard warranty covering defects in materials and workmanship, with optional extended coverage available for long-term peace of mind. ABB’s global technical support team provides 24/7 assistance for troubleshooting, configuration, and system integration, ensuring minimal downtime and optimal performance. Customers can access detailed documentation, software updates, and training resources through ABB’s digital platforms, empowering them to maximize the module’s capabilities and maintain operational excellence.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide