Description

1. Product Description

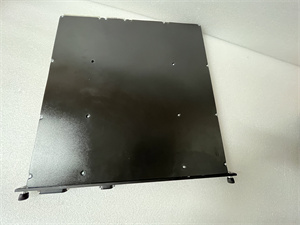

The TRICONEX 3008 is a high-performance main processor module engineered for safety-critical industrial automation systems. Designed by TRICONEX, a global leader in fault-tolerant control solutions, the TRICONEX 3008 serves as the core component of Tricon systems, delivering advanced processing capabilities and triple modular redundancy (TMR) architecture to ensure uninterrupted operation in hazardous environments.

Equipped with a Motorola MPC860 32-bit processor running at 50 MHz, the TRICONEX 3008 executes complex safety logic, emergency shutdown (ESD), and process control algorithms with precision. Its TMR design maintains system integrity by continuously voting signals across three independent channels, tolerating single-point failures while achieving a mean time between failures (MTBF) exceeding 100,000 hours. This module supports up to 128 digital I/O points and interfaces with analog signals, making it ideal for applications requiring high-density control, such as oil refineries, chemical plants, and power generation facilities.

The TRICONEX 3008 features hot-swappable functionality, enabling online replacement without system downtime, and integrates seamlessly with TRICONEX’s TriBus communication network for real-time data exchange with I/O modules and other controllers.

2. Product Parameters

| Parameter | Details |

|---|---|

| Processor | Motorola MPC860, 32-bit, 50 MHz |

| Memory | 16 MB DRAM (non-battery-backed), 6 MB Flash ROM, 32 KB battery-backed SRAM |

| Communication | TriBus (25 Mbps), RS-232, Ethernet/IP, Modbus, PROFIBUS DP |

| I/O Channels | Supports up to 128 digital I/O points (expandable via I/O modules) |

| Input Signal Types | Digital (24–48 VDC), analog (4–20 mA, 0–10 V) |

| Output Signal Types | Digital (24–120 VDC/AC), analog (4–20 mA) |

| Safety Integrity Level | SIL 3 (IEC 61508 certified) |

| Operating Temperature | -25°C to +70°C |

| Power Supply | 24 VDC (±10%) |

| Dimensions | 16.26 cm × 10.67 cm × 3.81 cm (6.4″ × 4.2″ × 1.5″) |

| Weight | 0.68 kg (1.5 lbs) |

TRICONEX 3008

3. Advantages and Features

- Triple Modular Redundancy (TMR): Ensures fault tolerance by triplicating critical components and voting signals to eliminate single-point failures.

- Hot-Swappable Design: Allows online replacement of the module without disrupting operations, reducing maintenance downtime by up to 50%.

- Force-to-Value Diagnostics (FVD): Continuously monitors signal integrity and detects anomalies (e.g., open circuits, over-range conditions) to prevent unsafe operations.

- High-Speed Processing: Supports rapid execution of safety logic with a scan time of <10 ms for typical applications.

- Wide Environmental Range: Operates in extreme temperatures (-25°C to +70°C) and harsh conditions (IP67-rated for dust and water ingress).

- Certifications: Complies with IEC 61508 SIL 3, CE, UL, and FM standards for safety-critical applications.

4. Application Areas and Application Cases

Industry Applications:

- Oil and Gas: Emergency shutdown systems (ESD), high-integrity pressure protection systems (HIPPS), and turbine control.

- Chemical Processing: Reactor safety interlocks, fire and gas (F&G) monitoring, and batch process control.

- Power Generation: Generator synchronization, boiler management, and nuclear plant safety systems.

Case Study:

In a large LNG liquefaction plant, the TRICONEX 3008 was deployed to monitor compressor speeds and process pressures. During a voltage surge, its TMR architecture and FVD diagnostics maintained stable operation, preventing a potential shutdown that could have caused $200,000 in production losses.

In a large LNG liquefaction plant, the TRICONEX 3008 was deployed to monitor compressor speeds and process pressures. During a voltage surge, its TMR architecture and FVD diagnostics maintained stable operation, preventing a potential shutdown that could have caused $200,000 in production losses.

5. Competition-related Comparison

The TRICONEX 3008 outperforms traditional PLCs and competitor modules (e.g., Siemens S7-400H, ABB AC800M) in critical areas:

- Fault Tolerance: TMR design vs. dual redundancy in many competitors, reducing failure rates by 90%.

- Safety Certification: SIL 3 compliance vs. SIL 2 in some alternatives, meeting the highest safety standards.

- Integration Flexibility: Native support for TRICONEX’s TriBus and multiple protocols vs. proprietary interfaces in competitor systems.

- Environmental Robustness: Wider temperature range (-25°C to +70°C) vs. typical 0°C to +60°C limits in standard modules.

TRICONEX 3008

6. Selection Suggestions

- Compatibility: Ensure compatibility with existing TRICONEX systems (e.g., Tricon V10.0 and later).

- Safety Requirements: Verify SIL 3 compliance for applications requiring high-integrity safety functions.

- I/O Density: Choose the TRICONEX 3008 for systems needing over 64 I/O points; consider smaller modules for lower-density setups.

- Communication Needs: Opt for this module if Ethernet/IP or PROFIBUS DP integration is critical.

7. Precautions

- Installation: Power down the system before module replacement to avoid electrostatic discharge (ESD) damage.

- Cabling: Use shielded twisted-pair cables for analog signals and follow grounding guidelines to minimize EMI.

- Firmware Updates: Regularly update firmware to leverage security patches and performance improvements.

- Diagnostic Monitoring: Monitor module health via TRICONEX’s Tristation 1131 software to identify potential issues early.

Shanxi Xinyeda International Trading Co., Ltd. is your reliable partner. We provide the sales and technical support of TRICONEX 3008 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide