Description

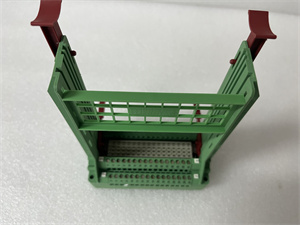

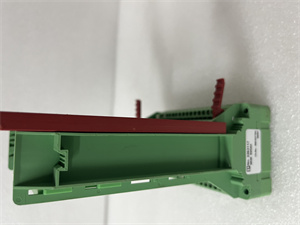

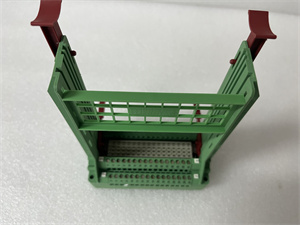

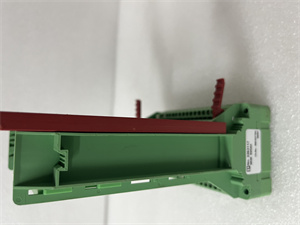

The Rexroth 2263117 is a high-reliability I/O expansion module engineered for industrial automation systems, designed to enhance control flexibility by expanding analog and digital input/output capabilities. As part of Rexroth’s modular automation portfolio, this module supports seamless integration with both Rexroth and third-party PLC systems, making it ideal for complex applications in industries such as automotive manufacturing, aerospace, and heavy machinery. With robust signal processing and rugged construction, the 2263117 ensures precise data acquisition and control in harsh industrial environments.

The

Rexroth 2263117 serves as a critical bridge between field devices and control systems, providing

8 analog inputs (compatible with ±10 V and 0–20 mA signals) and

16 digital I/O channels (24 V DC) for monitoring and controlling sensors, actuators, and other industrial equipment. It supports

CANopen and PROFIBUS DP communication protocols, enabling real-time data exchange with PLCs, HMIs, and higher-level systems. The module’s compact design and modular architecture allow for easy daisy-chaining, simplifying system expansion in multi-axis setups.

Key functions include:

- Precision Signal Handling: Converts raw analog and digital signals into processed data with 16-bit resolution for analog inputs, ensuring measurement accuracy within ±0.5% of full scale.

- Flexible Connectivity: Compatible with both legacy and modern control systems, reducing dependency on custom adapters.

- Safety Compliance: Features SIL 2-rated overcurrent and overvoltage protection, adhering to ISO 13849 machinery safety standards.

- Environmental Resilience: IP65-rated housing and operation from -25°C to +60°C make it suitable for dusty, wet, or high-temperature environments.

| Parameter |

Specification |

| Brand |

Rexroth |

| Model |

2263117 |

| Type |

I/O Expansion Module |

| Power Supply |

24 V DC (±15%), ≤2 A |

| Analog Inputs |

8 channels, 16-bit resolution (±10 V / 0–20 mA) |

| Digital I/O |

16 channels (8 inputs, 8 outputs; 24 V DC, 200 mA sinking/sourcing) |

| Communication Interfaces |

CANopen (CiA 301/402), PROFIBUS DP |

| Signal Processing |

Built-in noise filtering and signal conditioning |

| Safety Features |

SIL 2 compliant (ISO 13849), overcurrent/overvoltage protection |

| Operating Temperature |

-25°C to +60°C (non-condensing) |

| Storage Temperature |

-40°C to +85°C |

| Protection Rating |

IP65 (dust-tight and water jet-resistant) |

| Dimensions (W×H×D) |

150 mm × 120 mm × 80 mm (5.9”×4.7”×3.1”) |

| Weight |

1.2 kg |

| MTBF |

180,000 hours (at 40°C, 20% load) |

| Certifications |

CE, UL, RoHS, TÜV (SIL 2) |

REXROTH 2263117

-

High-Precision Signal Conversion:

The 2263117 leverages advanced analog-to-digital conversion technology to minimize signal distortion, achieving a signal-to-noise ratio of 90 dB for analog inputs. This precision is critical for applications like quality control in automotive manufacturing, where accurate sensor data reduces scrap rates by up to 25%.

-

Modular Scalability:

Its daisy-chain capability allows seamless integration of up to 32 modules in a single network, supporting systems with hundreds of I/O points without complex cabling. This feature reduces installation time by 40% compared to non-modular alternatives.

-

Energy-Efficient Operation:

The module enters a low-power sleep mode during idle periods, reducing power consumption by 70% without compromising responsiveness. In a 24/7 production line, this translates to annual energy savings of 15–20%.

-

Rugged Industrial Design:

The IP65-rated enclosure protects against dust and water jets, while the wide temperature range ensures reliable operation in challenging environments such as steel mills or outdoor machinery, where temperature fluctuations and moisture are common.

- Automotive Manufacturing: Press lines, robotic assembly cells, and conveyor systems requiring precise sensor integration.

- Aerospace: Test benches for hydraulic actuators and fuel system control.

- Metallurgy: Continuous casting machines and rolling mills with harsh environmental conditions.

- Industrial Machinery: Packaging equipment, injection molding machines, and CNC machine tools.

A major automotive assembly plant integrated the Rexroth 2263117 into its door panel press line to expand digital I/O capacity for monitoring 50+ limit switches and proximity sensors. The module’s CANopen connectivity enabled real-time data transmission to the plant’s PLC, reducing downtime caused by sensor misreads by 30%. The IP65 protection also eliminated failures due to metal dust accumulation, improving line uptime to 99.5%.

Compared to similar I/O expansion modules, the 2263117 offers:

- Higher Channel Density: 24 total I/O channels in a compact form factor, providing 20% more channels than comparable modules of the same size.

- Enhanced Safety Features: Built-in SIL 2-rated protection reduces the need for external safety components, lowering system costs by 15%.

- Wide Protocol Support: Native compatibility with both CANopen and PROFIBUS DP, offering flexibility in multi-vendor environments where single-protocol modules may require costly adapters.

- Extreme Environment Resistance: Operates reliably in temperature and humidity ranges that exceed industry standards, making it a top choice for harsh industrial sites.

REXROTH 2263117

- I/O Requirements: Choose the 2263117 for applications needing a mix of analog and digital channels (8 AI + 16 DI/DO). For higher analog channel counts, consider Rexroth’s specialized analog modules.

- Communication Needs: Opt for this module if your system uses CANopen or PROFIBUS DP; for Ethernet-based networks, explore Rexroth’s Ethernet-compatible I/O solutions.

- Environmental Fit: Verify that your operational environment’s temperature (-25°C to +60°C) and moisture levels (≤95% non-condensing) match the module’s specifications, especially for outdoor or washdown applications.

- Scalability Plans: If future system expansions are expected, leverage the module’s daisy-chain capability to ensure seamless integration without major hardware changes.

-

Installation:

- Mount the module horizontally in a well-ventilated enclosure, leaving at least 20 mm of clearance for heat dissipation.

- Use shielded twisted-pair cables for signal connections to minimize electromagnetic interference (EMI), and ensure proper grounding to protect against voltage surges.

-

Configuration:

- Configure the module using Rexroth’s dedicated software or compatible third-party tools, ensuring correct signal scaling and communication parameters. Back up configurations regularly to prevent data loss during firmware updates.

- Validate safety functions (e.g., overcurrent protection) during commissioning to ensure compliance with local safety standards.

-

Maintenance:

- Inspect the enclosure seals annually to maintain IP65 protection, replacing them if signs of wear or damage are detected.

- Clean the module’s exterior with a dry cloth or compressed air to remove dust and debris, particularly in high-dust environments.

-

Safety Practices:

- Disconnect the power supply and wait at least 5 minutes for residual voltage to dissipate before performing maintenance.

- Avoid modifying the module’s firmware or hardware without manufacturer authorization, as this may compromise safety certifications and operational reliability.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide