Description

The

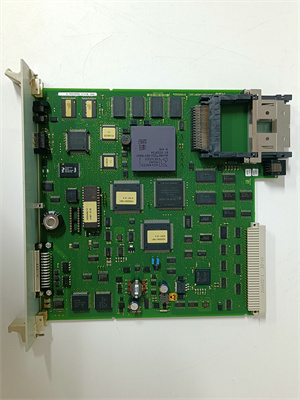

ABB 216VC62A HESG324442R13/B is a high-performance

variable frequency drive (VFD) module designed for precision motor control in industrial automation systems. As part of ABB’s

ACS880 drive series, the

216VC62A HESG324442R13/B combines advanced power electronics with intelligent control algorithms to optimize motor speed, torque, and energy efficiency. Engineered for demanding applications in manufacturing, mining, and process industries, this module serves as a critical component in conveyor systems, pumps, and fans, enabling seamless integration with ABB’s

800xA distributed control system (DCS).

Featuring a 2.2 kW power rating and 3-phase input/output capability, the 216VC62A HESG324442R13/B supports both scalar control and vector control modes, delivering precise motor regulation across a wide speed range (0–500 Hz). Its compact design (175 mm x 150 mm x 185 mm) and rugged construction ensure reliable operation in harsh environments, with built-in surge protection and EMC compliance to minimize interference from industrial machinery. The module’s HESG324442R13/B firmware version enhances compatibility with IoT platforms, allowing real-time monitoring of motor health via ABB’s Ability™ digital ecosystem. Positioned as a scalable solution, the 216VC62A HESG324442R13/B reduces energy consumption by up to 30% in variable-load applications while extending motor lifespan through gentle start/stop profiles.

| Parameter Name |

Parameter Value |

| Product Model |

216VC62A HESG324442R13/B |

| Manufacturer |

ABB |

| Product Type |

Variable Frequency Drive Module |

| Power Rating |

2.2 kW |

| Input Voltage |

3-phase, 380–480 V AC ±10% |

| Output Voltage |

3-phase, 0–480 V AC (variable) |

| Control Modes |

Scalar control, vector control |

| Frequency Range |

0–500 Hz |

| Communication Protocols |

Modbus RTU, Profibus DP, Ethernet/IP |

| Protection Features |

Overvoltage/undervoltage, overload, thermal shutdown |

| Operating Temperature |

-10°C to +50°C (with derating above +40°C) |

| Dimensions (W×H×D) |

175 mm × 150 mm × 185 mm |

| Mounting Method |

Panel-mounted or DIN rail (with adapter) |

| Certification |

CE, UL, IEC 61800-5-1, RoHS |

216VC62A HESG324442R13/B

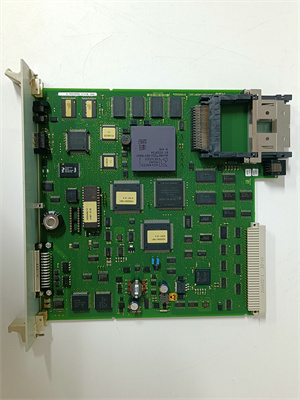

The 216VC62A HESG324442R13/B leverages ABB’s Direct Torque Control (DTC) technology to achieve torque response within 1 ms, ensuring precise control even under sudden load changes. In a paper mill’s winder application, this capability maintains consistent tension on the paper roll, reducing waste from tears or wrinkles. The module’s adaptive programming allows customization of acceleration/deceleration ramps, making it suitable for sensitive processes like pharmaceutical mixing, where gentle motor starts are critical to product quality.

With built-in energy optimization (EO) mode, the drive automatically adjusts motor flux to minimize power consumption during low-load periods, such as idle conveyor belts in food packaging lines. The HESG324442R13/B firmware includes predictive diagnostics that monitor parameters like bearing wear (via vibration analysis) and winding temperature, triggering alerts before failures occur. For example, in a water treatment plant’s pump system, early detection of rising motor temperatures can prevent costly downtime by scheduling maintenance during planned outages.

The module’s sleek enclosure and modular design simplify installation in space-constrained control panels, while its plug-and-play connectivity with ABB’s

PLCnext Technology reduces commissioning time by 50%. The dual-channel communication interface (Ethernet/IP and Profibus DP) enables seamless integration with both legacy and modern control systems, making it ideal for retrofitting projects in automotive factories or chemical plants. The intuitive keypad interface allows on-site parameter adjustment, while remote configuration via ABB’s

DriveWindow software enhances operational flexibility.

216VC62A HESG324442R13/B

The ABB 216VC62A HESG324442R13/B excels in industries requiring dynamic motor control and energy savings:

- Manufacturing: Controls conveyor belts, robotic arms, and spindle motors in automotive assembly lines. In a tire factory, the drive’s vector control mode ensures precise speed matching between extruders and calenders, improving product consistency.

- Mining and Metals: Drives slurry pumps and crushing equipment in mineral processing plants. Its rugged design withstands dust and vibration, while the wide temperature range supports outdoor installations in harsh climates.

- Food and Beverage: Manages mixers, bottling machines, and packaging lines, where hygienic design and quiet operation are critical. The drive’s EO mode reduces energy costs in 24/7 production facilities, such as breweries or dairy plants.

- HVAC Systems: Optimizes fan and chiller motors in commercial buildings, adjusting speed based on real-time demand. This reduces noise levels in office complexes while cutting energy usage by up to 40%.

- ABB 216VC63A HESG324443R14/C: A higher-power variant (3 kW) with built-in braking resistor support for heavy-duty applications.

- ABB ACS880-01-003A-3: A pre-configured drive system featuring the 216VC62A module, optimized for plug-and-play deployment.

- ABB PM510-24: A motor protection module that integrates with the 216VC62A to provide comprehensive overload and phase failure protection.

- ABB CI592: A PROFINET interface module that enhances the drive’s connectivity in industrial IoT networks.

- ABB TB532: A terminal block accessory for secure field wiring, compatible with the module’s analog and digital inputs.

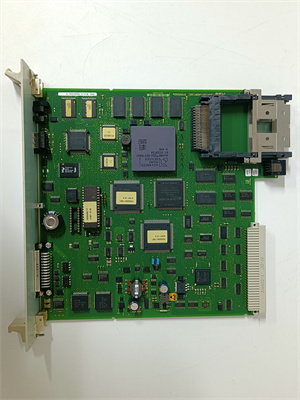

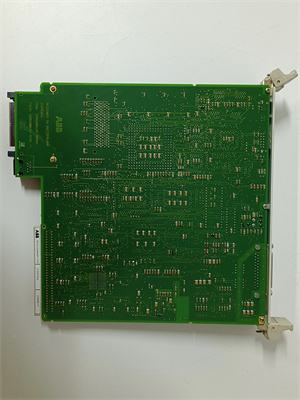

Pre-installation preparation: Ensure the control panel has adequate ventilation (cooling airflow ≥2 m/s) and ground the 216VC62A HESG324442R13/B using a 4 mm² copper wire to comply with EMC standards. Connect power cables to the designated L1/L2/L3 inputs and motor leads to T1/T2/T3 outputs, using shielded twisted-pair cables for signal wiring. Configure the drive’s parameters (e.g., motor rated voltage, control mode) via the keypad or DriveWindow software, and validate motor rotation direction before full-load operation.

Maintenance recommendations: Inspect the module’s cooling fans quarterly for dust accumulation, cleaning them with compressed air in dusty environments like cement plants. Monitor drive temperature using the built-in display, ensuring it remains below +40°C to avoid derating. Update firmware annually to access new features, such as enhanced cybersecurity protocols, and test the drive’s fault response by simulating an overload condition via the diagnostic menu. Replace capacitors every 5 years as part of preventive maintenance to maintain optimal performance.

ABB stands behind the 216VC62A HESG324442R13/B with a 5-year warranty, reflecting confidence in its durability and performance. ABB’s global service network provides 24/7 technical support, including remote diagnostics and on-site commissioning, to minimize downtime. The module’s compliance with international standards and rigorous testing (e.g., 10,000-hour load cycles) ensures long-term reliability. For critical applications, ABB offers Total Care plans, including annual health checks and priority access to spare parts, ensuring uninterrupted operation and maximizing return on investment. By combining precision control, energy efficiency, and robust design, the 216VC62A HESG324442R13/B sets a benchmark for variable frequency drive technology in industrial automation.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide