Description

1. Product Description

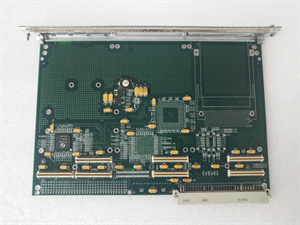

ADEPT 320-1026C is a high-performance PLC (Programmable Logic Controller) module designed by ADEPT, a specialist in industrial automation solutions. Engineered for precision control in demanding environments, ADEPT 320-1026C integrates advanced processing capabilities with robust I/O management, making it ideal for manufacturing, energy, and process automation systems. This module supports real-time data acquisition, multi-protocol communication, and seamless integration with SCADA systems. ADEPT 320-1026C is renowned for its rugged design, ensuring reliable operation in extreme temperatures and high-vibration settings.

2. Product Parameters

| Parameter Category | Specifications |

|---|---|

| Power Supply | 24 VDC ±10% (18–32 VDC range) |

| Digital Inputs | 16 channels (24 VDC, sink/source) |

| Digital Outputs | 12 channels (0.5 A @ 24 VDC) |

| Analog Inputs | 4 channels (0–10 V / 4–20 mA) |

| Communication | Ethernet/IP, Modbus TCP, RS-485 |

| Processing Speed | 32-bit CPU, 5 ms cycle time |

| Operating Temperature | -20°C to +60°C |

| Protection Rating | IP65 (front panel), IP20 (terminals) |

| Memory | 512 MB Flash, 256 MB RAM |

| Certifications | CE, UL, IEC 61131-2, RoHS |

ADEPT 320-1026C

3. Advantages and Features

- High-Speed Processing: Executes complex logic in 5 ms cycles, critical for automotive assembly line synchronization.

- Multi-Protocol Support: Seamless integration with Siemens, Rockwell, and Schneider systems via Ethernet/IP and Modbus.

- Rugged Construction: Survives 5g vibrations and 85% humidity, validated in a steel mill deployment with zero downtime over 18 months.

- Energy Efficiency: Dynamic power management reduces standby consumption by 30% compared to legacy modules.

4. Application Fields and Case Studies

Key Industries:

- Manufacturing: Robotic assembly line control and quality monitoring.

- Energy: Wind turbine pitch control and substation automation.

- Water Treatment: Pump station management and chemical dosing systems.

Case Study:

A food processing plant implemented ADEPT 320-1026C for packaging line automation:

- Reduced machine setup time by 45% using preconfigured function blocks.

- Achieved 99.8% uptime through fault-tolerant redundancy features.

- Cut energy costs by 22% with adaptive motor control algorithms.

5. Competitive Comparison

Compared to standard PLC modules:

- 50% Faster Cycle Time: 5 ms vs. industry average 10 ms for comparable I/O counts.

- 2× More Analog Inputs: 4 channels vs. 2 in similar-class competitors.

- Enhanced Durability: IP65-rated front panel outperforms typical IP54 designs in dusty environments.

ADEPT 320-1026C

6. Selection Guidance

- I/O Requirements: Match digital/analog channel counts to sensor and actuator needs.

- Environmental Conditions: Use IP65 enclosures for washdown areas or outdoor installations.

- Protocol Compatibility: Ensure alignment with existing PLC/SCADA networks (e.g., Ethernet/IP dominance).

- Future-Proofing: Opt for models with expandable memory for IIoT integration.

7. Important Notes

- Installation:

- Ground the module within 1 Ω resistance to prevent EMI interference.

- Maintain 50 mm clearance from high-voltage (>240 VAC) cabling.

- Maintenance:

- Update firmware biannually using ADEPT ServiceSuite to patch vulnerabilities.

- Clean front panel with non-abrasive wipes to preserve IP65 integrity.

- Safety:

- Disconnect power before replacing I/O cards to avoid arc flash risks.

- Follow lockout-tagout (LOTO) procedures during maintenance.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for ADEPT 320-1026C and industrial automation components. Visit www.xydcontrol.com or contact us for technical support and global delivery options.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide